An important new tool that could help to drastically reduce buildings' climate impacts has been made freely available.

It is a revolutionary update of a “bible" on the embodied energy of hundreds of materials - anything from carpets and concrete to timber, insulation and plastics.

The widely used and authoritative ICE Database - 'Embodied Carbon: the Inventory of Carbon & Energy (ICE)' - is aimed at the manufacturing, construction and refurbishment industries, including designers, architects and policymakers.

It provides an invaluable means of telling specifiers what to avoid and what to use in the struggle to reduce the environmental impact of construction and other products.

What is embodied energy?

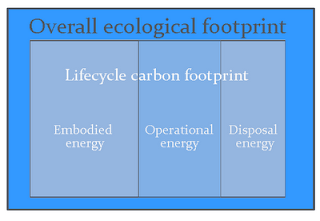

To reduce the level of climate change it is necessary to reduce emissions of global warming gases. These occur at every point in the life of a material or product, giving rise to the "life-cycle carbon footprint".

The “embodied energy" component of this overall figure is that used in the manufacturing process and is distinguished from the "operational energy" – that used in its lifetime. Then there is the environmental cost of its final disposal – whether it is landfilled or recycled etc.

If, for example, the product is concrete, it will take account of all the energy involved in quarrying, transportation and manufacture.

Usually, the impacts of other global warming gases like methane and HCFCs are converted into carbon-equivalent values for ease of comparison.

Why is it useful?

All products contain materials and in particular buildings can be with us for between 30 and 100 or more years. The building sector is responsible for 21% of global carbon dioxide-equivalent emissions: 8% through emissions from primary fuel types and 13% from the electricity demand for residential and commercial buildings.

As buildings become more energy efficient in operation, the embodied energy component of their overall footprint becomes proportionally more significant.

A recent report from the South West Regional Development Agency (SWRDA) on sustainable offices summarised that the embodied carbon impacts (construction, plus demolition) accounted for about a third of the whole life carbon impact.

Similarly, the RICS redefining zero report estimated the contribution of embodied carbon to be 20% for supermarkets, 30% for houses, 45% for offices and an incredible 60% for warehouses (usually unheated).

Last autumn the final report was published of the UK Low Carbon Construction Innovation and Growth Team (IGT), chaired by Paul Morrell (the UK Government Chief Construction Advisor). It had been asked by the government to consider how the construction sector could meet the low carbon agenda.

It made many recommendations, and on embodied carbon said that "as soon as a sufficiently rigorous assessment system is in place, the Treasury should introduce into the Green Book a requirement to conduct a whole-life (embodied + operational) carbon appraisal and that this is factored into feasibility studies on the basis of a realistic price for carbon".

Further, "that the industry should agree with Government a standard method of measuring embodied carbon for use as a design tool for the purposes of scheme appraisal".

A wealth of information

ICE is such a tool. It includes annexes on methodologies for metal recycling and explanations of how the values for carbon impacts have been calculated.

Summary sheets for each material expand into detailed fact sheets and graphs, giving a breakdown of the components of the impact, and how it has varied over the last 15 years.

For example, we learn that the impact of aggregates has been reduced by 1/5, because the UK energy mix has changed to include more natural gas.

In the important area of insulation, we learn that cellulose, typically made from recycled newsprint, has by far the lowest embodied energy (a maximum of 3.3MJ/Kg) even compared to other natural materials.

Rockwool is at 16.8, but polystyrene and other plastic insulation boards and foams, widely used in industry, are in the range of 99-109MJ/Kg. That is 30 times more than cellulose.

This means that cellulose should really be used universally by builders and refurbishment programmes in preference, despite the fact that it might take up more room.

It's important to realise that the global warming effects of the manufacture of products happens from the moment they are made, whereas the energy-saving benefit of insulation is only in the future.

Natural materials also contain carbon that has been locked up from the atmosphere during their growth (although ICE gives an average figure for the embodied energy of timber of 9.43 MJ/Kg).

So if there is a choice between timber and uPVC windows or doors, for example, uPVC has an embodied energy 10 times greater, of 94.7MJ/Kg.

The spreadsheets also include CIBSE data on material properties.

ICE is a major achievement, and is produced with the non-profit Building Services Research & Information Association (BSRIA). It is available to purchase and free to members.

The University of Bath, where project lead Craig Jones is employed, has charitably made a free Excel file version available.

Also for those with an interest in whole life carbon in buildings is this Sustain report on operational versus embodied energy.

Other sources of information

There are are other sources of comparable information:

• The Institute of Civil Engineers (ICE) Civil Engineering Standard Method of Measurement 3 (CESMM3) which includes carbon and prices for every material and unit of work, enabling users to calculate not just the economic, but also the embodied carbon of projects.

• The Hutchins 2010 UK Building Blackbook (The Capital Cost and Embodied CO2 Guide, Volume two: major works) which now includes both cost and embodied carbon for construction works.

• The Royal Institution of Chartered Surveyors (RICS) working group examining embodied carbon.

• The Institution of Structural Engineers (IStructE) soon-to-be published short guide on embodied carbon.

• BS 8903:2010 Principles and Framework for Procuring Sustainably

• PAS 2060:2010 Specification for the Demonstration of Carbon Neutrality.

No comments:

Post a Comment